Thumbs are one of the most popular attachments for excavators in the US market. A thumb attachment on your excavator turns your machine into a grapple/material handler instead of just a digging tool. The concept is simple and often more affordable than a dedicated grab or grapple attachment.

Contents

What is an Excavator Thumb?

So When Do You Need a Thumb?

How to Install a Thumb?

Where to Purchase?

Other FAQ

Conclusion

What is an Excavator Thumb?

A thumb, also known as a clamp, is a vital excavator attachment that can add productivity and flexibility. You should know when and how to use it properly. Attachments hold the power to decide how effective your excavator will be at a certain job. It is essential to understand what options you have and how to make the right decision.

So When Do You Need a Thumb?

“Anytime you need an attachment to grab something that doesn’t fit in the bucket,” says Aaron Kleingartner, dealer and product marketing manager at Doosan Infracore North America . “The thumb is an extra resource for you to help secure that material or to maintain a grip so you don’t lose it as you’re working with the machine. So, if you’re working in scrap or recycling, a thumb is a fantastic addition to the machine.”

With a Hydraulic Thumb, your excavator goes from digging to complete material handling. An Excavator Thumb makes it easier to pick, hold and move awkward material such as rocks, concrete, branches, and debris that does not fit into the bucket.

Excavator thumbs are often only used with the standard digging bucket but can often be more efficient in conjunction with other attachments such as rakes & stump pullers etc. A thumb and rake combination is one of our more popular setups for customers working in a land clearing where they are moving a lot of trees and logs, for example.

How to Installing a Thumb?

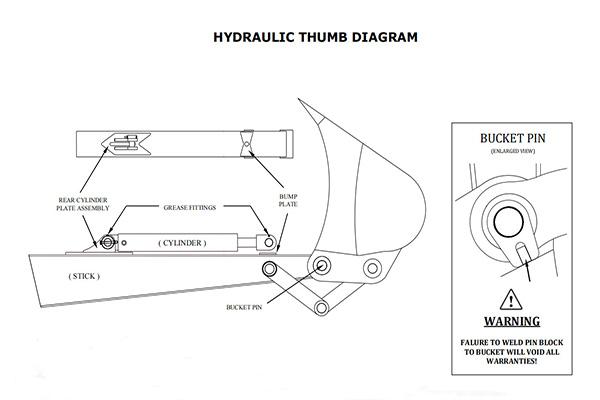

Since there are a few different thumb designs, they are all installed slightly differently, however, the principle is going to be the same across the board. We recommend having your thumb installed by an experienced excavator dealer/mechanic.

In the US, most machines now come with a hydraulic thumb from the factory. If not, they often have a cylinder base plate already mounted on the excavator so there will be no need to weld the base plate yourself. However, when ordering a thumb from any manufacturer, make them aware if your machine already has a thumb base plate installed, as they will have to provide a thumb cylinder that matches this base plate, which may be different from their standard mounting position, pin size, etc.

If your machine does not have any thumb mounting plates installed already, don’t worry, as all hydraulic thumbs will come with a base plate as standard. Each thumb manufacturer may provide slightly different installation instructions but they will all be very similar.

This is not an exhaustive step-by-step installation process, but rather an overview of the critical steps of the process.

Step 1: Make sure you have all the pieces or hardware that you will need. Look through your manual for a list and have the tools necessary handy.

Step 2: Install the base or the thumb on the end of the arm pin.

Step 3: Install the cylinder from the thumb to the arm of the machine.

Step 4: Install the hoses to connect the thumb and mini excavator controls.

Step 5: Final inspection. Make sure all the parts are secure and in the proper place before operating the machine.

Where to Purchase?

“They’re designed to be able to mesh with the teeth of the excavator’s buckets so that they overlap,” Kleingartner says. “Each manufacturer has a design that incorporates the design of the bucket into the design of the thumb. The bucket and the thumb mesh and they work together, not against each other.”

Shandong Mingde Machinery Co., Ltd. is a leading manufacturer that offers all thumb variations in Jining, China. MONDE has been building thumbs for over 15 years and provides some of the highest quality but also affordable attachments in the market.

As mentioned previously in the article, most thumbs are built to suit the specifications of the machine and also the customer. For this reason, all thumbs from MONDE are built to order. This results in a usual lead time of 2-3 weeks to manufacture. However, this means that you get the correct width, length, and a number of tines on your thumb to perfectly match with the bucket.

Many other attachment suppliers keep generic thumbs in stock that are meant to suit a range of machines and bucket sizes. However, this often means that the thumb doesn’t properly match the bucket’s cutting edge or teeth. This is why we believe it is important to wait on a short lead time and get your thumb built specifically for your needs.

Other FAQ:

What is the PSI?

· PSI stands for Pound-Force per Square Inch. The PSI is how much pressure will be going to the hydraulic cylinder.

· PSI Warning: PSI must be set at 75% or less.

What size thumb do I need, or how do I measure my machine?

· Warning: We suggest you measure your machine before purchasing. Measure your machine with the bucket at a 90-degree angle. Measure straight from the teeth of the bucket to the arm of your machine.

Where do I get hydraulic hoses for my hydraulic thumb?

· You can purchase hydraulic hoses and fittings at any local hose and fitting store near you.

How do i know if my machine can use a hydraulic Thumb?

· Not all machines are plumbed (set-up) for hydraulic attachments. If the machine is plumbed (set-up) for hydraulics you will see hydraulic lines on the arm of your machine. You can also call the dealer of your machine to find out. If you do not have hydraulic capabilities we offer Mechanical thumbs.

Conclusion

In conclusion, there are many thumb variations in the market that all suit specific needs and applications. Often the price is one of the most important factors but can vary widely between thumb setups, even on the same machine.

We believe that thumbs should be built specifically for the machine and bucket, so for that reason we provide thumbs that are built to a high standard and designed specifically for your machine.

If there is anything that we did not cover and that you would like to ask, you can contact us here!

We appreciate you taking the time to read through our guide to excavator thumb attachments.